喷涂喷焊

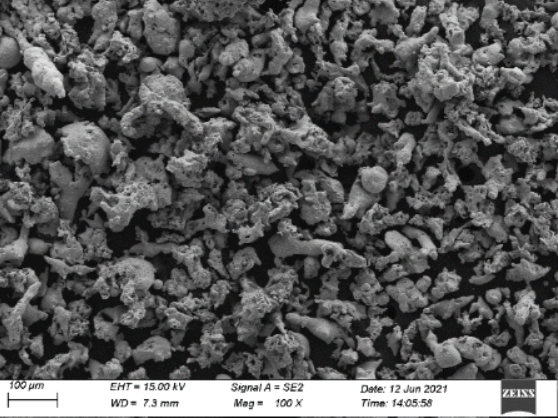

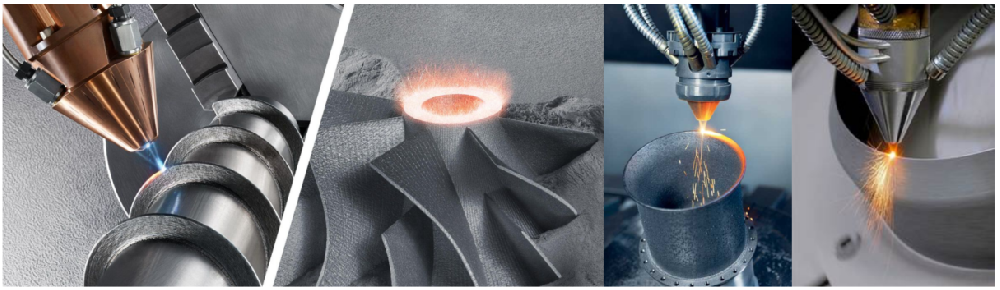

热喷涂/喷焊粉末 Thermal spraying/welding powder

热喷涂/喷焊粉末 Thermal spraying/welding powder

热喷涂/喷焊粉末 Thermal spraying/welding powder

l 产品应用/Applications

n 镍基合金粉末

1、自熔性镍基合金粉末 Nickel base self-melting alloy powder

牌号 Grade | 硬度 HRC | 粒度/目 Particle Size/mesh | 化学成分 Chemical Composition | 典型用途 Typical Application | |||||||||

C | Cr | Si | Fe | Mo | Co | Mn | B | Others | Ni | ||||

Ni15AA | 15 | 180/500 | 0.03 | 0.46 | 2.3 | 0.46 | 0.09 | 0.9 | Cu:20 | Bal. | WC系列喷焊层打底层Bonding layer for WC coatings | ||

Ni20M | 20 | 180/500 | 0.03 | 4.5 | 2 | 0.7 | Bal. | 玻璃模具、各种成型模等Glass molds or other molds | |||||

Ni22AA | 22 | 180/500、100/270 | 0.2 | 0.1 | 2.85 | 0.5 | 0.5 | 1.45 | Bal. | 玻璃模具、各种成型模Glass molds or other molds | |||

Ni22M1 | 26 | 180/500 | 0.03 | 0.5 | 3 | 0.5 | 0.5 | 1 | Bal. | 玻璃模具、各种成型模 Glass molds or other molds | |||

Ni25 | 25 | 180/500、150/300 | 0.2 | 3.5 | 8 | 1.5 | Bal. | 玻璃模具、各种成型模 Glass molds or other molds | |||||

Ni30AA | 30 | 180/500、150/300 | 0.15Max | 2.5 | 2.6 | 1 | 3 | 1.4 | Bal. | 滑轨、齿轮齿 Rails, gear teeth | |||

Ni35AA | 35 | 150/300 | 0.2 | 4 | 3.2 | 1.4 | 0.1 | 1.6 | Bal. | 玻璃模具、阀座 Glass molds or valve seats | |||

Ni35 | 35 | 150/300 | 0.3 | 10.5 | 3.5 | 10 | 2 | Bal. | 玻璃模具、各种成型模 Glass molds or other molds | ||||

Ni40AA | 40 | 150/300 | 0.3 | 7.5 | 3.5 | 2.3 | 0.1 | 1.7 | Bal. | 螺旋送料器、模芯等Screw conveyors, forging mold parts | |||

Ni46M | 46 | 180/500 | 0.05 | 6.54 | 2.8 | 1 | 1 | Bal. | 玻璃模具、各种成型模 Glass molds or other molds | ||||

Ni50AA | 50 | 150/300 | 0.45 | 11 | 4 | 2.7 | 1 | 2.2 | Bal. | 冲头、阀门、柱塞 Forging heads, valves | |||

Ni55 | 53 | 150/300、 53/20μm | 0.4 | 15 | 4.3 | 5.0Max | 2.5 | 3.1 | Cu:2.5 | Bal. | 磨具、凸轮、柱塞及排气阀Grinding tools, cam gears, pistons, exhaustvalves | ||

Ni65AA | 56 | 100/270 | 1 | 18 | 5.3 | 5.0Max | 1.9 | Bal. | 阀门、模具、螺杆Valves,molds,extrusion screws | ||||

Ni60AA | 60 | 150/300、 53/20μm | 0.78 | 15.9 | 4.55 | 5.0Max | / | / | / | Bal. | 柱塞、阀门、泵叶、螺杆等Pistons, valves,pump blades,extrusion screws | ||

Ni60A | 60 | 150/300 | 0.7 | 15 | 4 | 8.0Max | 3.2 | Bal. | 柱塞、阀门、泵叶、螺杆等Pistons,valves, pump blades,extrusion screws | ||||

Ni60 | 60 | 150/300 | 0.8 | 16 | 4 | 15.0Max | 3.2 | Bal. | 柱塞、阀门、泵叶、螺杆等Pistons, valves, pump blades,extrusion screws | ||||

Ni60S | 60 | 150/400 | 0.8 | 15.5 | 3.8 | 0.1 | 3.4 | Bal. | 螺杆等Extrusion screws | ||||

ND500 | 52 | 100/270 | 1.2 | 20.5 | 2.9 | 3.0Max | 5.5 | 13 | 2.3 | Bal. | 专门用于挤出机、注塑机螺杆PTA堆焊Specifically used for extrusionequipment ,injection molding extrusion screws oxyacetylene weld overlaying | ||

NF601 | 60 | 150/400 | 0.78 | 15.5 | 3.2 | 5.0Max | 2.5 | 3 | 4 | Bal. | 专门用于挤出机、注塑机螺杆OXY堆焊Specifically used for extrusionequipment, injection molding extrusion screws, oxyacetylene weld overlaying | ||

Ni60B | 60 | 150/300、 53/20μm | 0.6 | 17.1 | 3.1 | 25 | 4 | Bal. | 柱塞、挤压模、泵叶、螺杆等Pistons, extrusion molds, pump blades, extrusion screws | ||||

Ni60AACuMo | 58 | 150/300、 53/20μm | 0.5 | 15.5 | 4 | 3.0Max | 2.5 | 3.5 | Cu:2.5 | Bal. | 柱塞、挤压模、泵叶、螺杆等Pistons, extrusion molds,pump blades, extrusion screws | ||

Ni60ACuMo | 60 | 150/300 | 0.8 | 15.5 | 4 | 15.0Max | 1 | 3.5 | Cu:1. | Bal. | 柱塞、挤压模、泵叶、螺杆等Pistons, extrusion molds, pump blades, extrusion screws | ||

Ni60W | 62 | 150/300 | 0.8 | 16 | 4 | 15.0Max | 3.3 | Bal. | 柱塞、泵叶等 Pistons, pump blades | ||||

Ni60CuMoW | 60 | 300/500 | 0.6 | 16 | 4 | 4 | 2 | 4 | Cu:2.0 | Bal. | 柱塞、泵叶、硬密封球阀等Pistons, pump blades, ball valves | ||

Ni220 | 31 | 100/270 | 0.15 | 5 | 3 | 2 | 2.2 | Al:0.9 | Bal. | 玻璃模具各种成初模Glass molds for preliminary molding | |||

Ni220M | 26 | 100/270 | 0.05Max | 4.5 | 3.2 | 3.0Max | 1 | Al:0.8 | Bal. | 玻璃模具各种成初模Glass molds for preliminary molding | |||

Ni330 | 37 | 100/270 | 0.1 | 5 | 3.5 | 6 | Cu:2.5 | 1.2 | Bal. | 玻璃模具各种成初模Glass molds for preliminary molding | |||

Ni22APTA | 28 | 100/270 | 0.05Max | 4.5 | 3.8 | 3 | 1 | Bal. | 玻璃模具各种成初模Glass molds for preliminary molding | ||||

2、镍基超合金 Nickel base super alloy powders

粉末 Powder | 化学成分 Chemical Composition | 粒度Size | 典型用途 Typical Application | |||||||||

C | Cr | Si | W | Fe | Mo | Co | Mn | 其他/Others | Ni | |||

NiCr20 | 0.2Max | 20 | 1.0 | 0.5Max | 0.5Max | Bal | 53-20μm | 超音速喷涂打底Bonding layer for WC coatings | ||||

NiCr50 | 1.0Max | 50 | 1.0 | 0.5Max | 0.5Max | Bal | 106-45μm | 造纸泵、电厂沸水器以及含V、S等腐蚀气体介质Pulp-making pump, power generation boilers, parts in a corrosive environment containing vanadium and sulphur | ||||

Ni625 | 0.1 | 23.0 | / | / | 5 | 8.0-10.0 | / | / | Bal | 53-20μm | 耐海水腐蚀部件、航天航海配件、化学工业Parts subject to seawater corrosion,such as, in aerospace or aeronautical industry and chemical processing | |

Ni718 | 0.05 | 19.0 | 0.35Max | / | 1.5Max | 3.0 | 0.5 | / | Nb=5.0 Ti=0.85 Al=0.5 | Bal. | 53-20μm | • 时效强化、耐高温、耐腐蚀 • 适用于航空航天、固定式燃气轮机、油田应用 |

Ni-C | 0.1 | 16.5 | 0.9 | 4.5 | 5.5 | 17.0 | 2.0Max | 0.9 | Bal | 53-20μm | 造纸机械Paper-making machine | |

Ni-SuperC | 0.05Max | 23.0 | 18.0 | Bal | 53-20μm | 造纸机械Paper-making machine | ||||||

Ni276 | 0.01Max | 15.5 | 0.03 | 4 | 16.0 | 2.5Max | 1.0 | Bal | 53-20μm | 需抗高温腐蚀和高温氧化场合 temperature oxidation | ||

Mn400 | 0.15Max | 1.25 | 1.5 | Ti:2.0 | 3.5 | Bal | 53-20μm | 化学、石化和海洋开发设备Chemical or petrochemical processing equipment parts | ||||

3、镍基包覆碳化钨型 Nickel Coated Tungsten Carbide Powders

粉末Powder | 硬度HRC | 化学成分Chemical Composition | 粒度Mesh Size | 典型用途Typical Application |

NiWC5 | 60 | 95%Ni60+5%WC | 150/300,150/400 | 螺杆、机筒、柱塞Extrusion screws, barrels, pistons |

NiWC10 | 62 | 90%Ni60+10%WC | 150/300,150/400 | 螺杆、机筒、柱塞Extrusion screws, barrels, pistons |

NiWC15 | 62 | 65%Ni60+15%WC | 150/300,150/400 | 阀门、柱塞 Valves, pistons |

NiWC20 | 63 | 65%Ni60+20%WC | 150/300,150/400 | 阀门、拉丝模、柱塞Valves,wire drawing dies, pistons |

NiWC25 | 63 | 65%Ni60+25%WC | 150/300,150/400 | 阀门、拉丝模、柱塞Valves, wire drawing dies, pistons |

NiWC35 | 65 | 65%Ni60+35%WC | 150/300,150/400 | 拉丝轮、风机叶片、螺旋输入器等Wire drawing pulling wheels, fen blades, screw conveyors |

n 钴基合金粉末 Cobalt base alloy powder

1、Co-Cr-W型

粉末 Powder | 硬度 HRC | 化学成分 Chemical Composition | 粒度 Mesh Size | 典型工艺 Typical Application | |||||||||

C | Cr | Si | W | Fe | Mo | Ni | Co | Mn | P | ||||

Co01 | 48-54 | 2.4 | 30 | 1 | 12 | ≤3.00 | ≤1.00 | ≤3.00 | Bal | ≤1.00 | 100/270 | 阀座、轴承、刀口、旋转密封环等Valve seats, bearings, cutting blades,seal rings | |

Co03 | 48-54 | 2.3 | 30 | 1 | 12 | ≤3.00 | / | ≤3.00 | Bal | / | 100/270 | 针阀座、导向辊、阀座等Needle valve seats, guide roils valve seats | |

Co06 | 38-44 | 1.2 | 30 | 1 | 4.5 | ≤3.00 | ≤3.00 | Bal | ≤1.00 | 100/270目、 300/500目 | 发动机气门,高温高压阀门,涡轮机叶片等Engine values, high temperature pressure valves, turbo engine blades | ||

Co156 | 1.6 | 28 | 1.1 | 4.0 | Bal | 100/270 | 汽车配件、军工产品 Automotive parts, military applications | ||||||

Co06H | 43-48 | 1.3 | 30 | 1.5 | 5.5 | 3.00Max | 0.8 | 3.00Max | Bal | l.0Max | 100/270 | 发动机气门、高温高压阀门、涡轮机叶片等 Engine valves, high temperature pressure valves,turbo engine blades | |

Co12 | 42-48 | 1.4 | 29 | 1.4 | 8.5 | ≤3.00 | ≤1.00 | ≤3.00 | Bal | ≤1.00 | 100/270 | 高温高压阀门、锯齿、螺旋推杆等High temperature pressure valves,saw teeth,extrusion screws | |

Co12B | 4549 | 1.3 | 30 | 1 | 5.5 | 3.0Max | 5 | 10.5 | Bal | l.0Max | 100/270 | 锯片导板Saw guide plates | |

Co12H | 48-53 | 1.7 | 30 | 1.7 | 7 | 2.0Max | 2.0 | 3.0Max | Bal | 0.5Max | 100/270 | 高温高压阀门、锯齿、螺杆High temperature pressure valves, saw teeth,extrusion screws | |

Co6113 | 43-48 | 1.8 | 27 | 4.0 | 6.0 | Bal | 100/270 | 腐蚀和磨损兼备工况 Resistance to corrosionand wear | |||||

Co107 | 40-44 (46-50) | 2.0 | 35 | 1 | 5 | 2.0Max | 24 | Bal | 1 | 100/270 | 加工硬化Work hardening | ||

Co19 | 48-56 | 1.8 | 31 | 1.0 | 11 | 3.0Max | 3.0Max | Bal | 1.0 | 100/270 | 切刀Cutting knives | ||

CoF | 37-44 | 1.6 | 26 | 1.1 | 12 | 3.0max | 0.5Max | 22.5 | Bal | 0.5Max | 100/270 | 发动机气门Engine valves | |

CoFH | 38-44 | 1.4 | 28 | 1.2 | 12 | 3.0Max | 0.8 | 22.5 | Bal | 0.5 | 100/270 | 发动机气门Engine valves | |

Co20 | 57-53 | 2.5 | 32 | 1 | 18 | ≤3.00 | ≤1.00 | ≤3.00 | Bal | ≤1.00 | 300/500 | 轴承套筒、耐磨板等Bearing sleeves, wear plates | |

Co07 | 30-36 | 0.4 | 26 | 0.9 | 5.5 | 3.0Max | 3.0Max | Bal | 0.3 | 100/270 | 汽轮机叶片、黄铜铸模、挤出模Steam turbine blades, brass casting molds, extrusion molds | ||

CoX-40 | 30-35 | 0.8 | 25.5 | 0.4 | 7.5 | l.OMax | l.OMax | 10.5 | Bal | 0.5Max | 0.04Max | 100/270 | 汽轮机耐热气冲蚀部件Steam turbine pans for resisting high temperature degradation and erosion |

Co31 | 30-35 | 0.4 | 25.5 | 0.8 | 7.5 | 2.0Max | 0.5Max | 10.5 | Bal | 0.5Max | 100/270 | 汽轮机耐热气冲蚀部件Steam turbine pans for resisting high temperature degradation and erosion | |

Co694 | 47-53 | 1.0 | 28 | 1 | 19 | 2.5Max | Bal | 1 | 100/270 | 汽轮机部件Steam turbine parts for resisting temperature degradation and erosion | |||

Co25 | 20Max | 0.05Max | 20 | 0.8 | 15 | 3.0Max | 8 | 10 | Bal | 1.3 | 100/270 | 热挤压模Hot extrusion molds | |

Co306 | 34-40 | 0.4 | 25 | 1 | 2.5 | 4.0Max | 6.0 | Bal | 1.0 | 100/270 | 红热钢带用热剪刀、夹具头、导向轮Steel hot rolling shears, clangs, guide rolls. | ||

Co238 | 20-26 | 0.1 | 26 | 1 | 20 | 3.0 | Bal | 1.0 | 100/270 | 锻模Forging dies | |||

Co190 | 57-63 | 3.3 | 26 | 0.8 | 14 | 3.0Max | l.0Max | 3.0Max | Bal | l.0Max | 100/270 | 石油钻头Oil drilling heads | |

Co400 | 48-54 | 0.08Max | 8.5 | 2.5 | 2.0Max | 29 | l.0Max | Bal | 0.5Max | 100/270、300/500 | 镀锌线轴套、衬套Galvanizing line bearing sleeves and shaft sleeves. | ||

Co400M1 | 0.08Max | 14 | 2.6 | 0.5Max | 26 | 0.5 | Bal | O.1Max | 100/270、300/500 | 耐高温腐蚀、镀锌线轴套、衬套To resist high temperature corrosion,galvanizing bearing sleeves,shaft sleeves | |||

Co400M2 | 46-52 | 0.08Max | 17 | 1.2 | 0.5Max | 22 | 0.5Max | Bal | 0.5Max | 100/270、300/500 | 耐高温腐蚀工况Resist high temperature corrosion,galvanizing bearing sleeves,shaft sleeves,natural gas engine valves | ||

Co800 | 52-58 | 0.08Max | 17.5 | 3.5 | 2.0Max | 29 | l.0Max | Bal | 0.5Max | 300/500 | 耐高温腐蚀、镀锌线轴套、衬套、天然气A气阀Resist high temperature degradation | ||

2、Co-Cr-Mo型

粉末 Powder | 硬度 HRC | 化学成分 Chemical Composition | 粒度 Mesh | 典型工艺 Typical Application | |||||||

C | Cr | Si | Fe | Mo | Ni | Co | Mn | ||||

Co706 | 38-43 | 1.2 | 29 | 0.5 | 3.0Max | 5 | 3.0Max | Bal | 1.0 | 100/270、300/500 | 耐蚀性要求较高的高温高压阀门 Pressure valves with high temperature corrosion resistance |

Co702 | 45-50 | 1.8 | 29 | 0.5 | 3.0Max | 9.0 | 3.0Max | Bal | 0.5 | 100/270 | 耐蚀性要求较高的高温高压阀门、螺杆 Pressure valves with high temperature corrosion resistance,extrusion screws |

Co701 | 50-56 | 2.5 | 31 | 0.5 | 3.0Max | 13.0 | 3.0Max | Bal | 0.5 | 100/270 | 耐蚀性要求较高的高温高压阀门、螺杆 Pressure valves with high temperature corrosion resistance |

Co720 | 54-60 | 2.5 | 33 | 0.5 | 3.0Max | 18 | 3.0Max | Bal | 0.8 | 300/500 | 耐蚀性要求较高的高温高压阀门 Pressure valves with high temperature corrosion resistance |

Co721 | 18-24 | 0.05Max | 30 | 0.6 | 8.0 | 4.0 | 0.3Max | Bal | 0.7 | 100/270 | 汽轮机耐汽蚀部件 Steam turbine erosion-resistant parts |

3、自熔性钴基粉

粉末 Powder | 硬度 HRC | 化学成分 Chemical Composition | 粒度 Mesh | 典型工艺 Typical Application | |||||||||

C | Cr | Si | W | Fe | Mo | Ni | Co | Mn | B | ||||

Co157 | 51-57 | 0.3 | 22 | 1.5 | 5.0 | 3.0Max | 3.0Max | Bal | 2.4 | 150/300 | 高温高压阀门 High temperature pressure valves | ||

Co158 | 40-46 | 0.8 | 29 | 1.5 | 5.5 | 3.0Max | ≤1.00 | ≤3.00 | Bal | ≤1.00 | 0.8 | 150/300 | 高温高压阀门 High temperature pressure valves |

Co158V | 45-50 | 1 | 30 | 1.2 | 8 | 3.0Max | 3 | Bal | 0.3Max | 0.8 | 200/400 | 摩托车气门 Motorcycle engine valves | |

CoWC35 | 57-63 | 2.4 | 12 | 2.6 | 33 | 3.0Max | 9 | Bal | 1.9 | 150/300 | 摩托车气门 Motorcycle engine valves | ||

CoSF6 | 40-46 | 0.6 | 18 | 2.3 | 7.5 | 3.0Max | l.0Max | 14 | Bal | 0.5Max | 1.7 | 150/300 | 镀锌线轴套、衬套 Galvanizing line bearing and shaft sleeves |

CoSF12 | 46-52 | 0.9 | 18 | 2.8 | 9 | 3.0Max | 14 | Bal | 0.5Max | 1.8 | 150/300 | 高温高压阀门、阀座 High temperature pressure valves and seats | |

CoSFl | 52-58 | 1.2 | 19 | 2.8 | 12 | 3.0Max | 12 | Bal | 0.5Max | 2.4 | 150/300 | 高温高压阀门、阀座 High temperature pressure valves and seats | |

CoSF20 | 59-64 | 1.5 | 19 | 3 | 15 | 2.0Max | 13 | Bal | 0.5Max | 3.0 | 150/300 | 高温高压阀门、阀座 High temperature pressure valves and seats | |

CoSFT400 | 55-60 | 0.1 | 10 | 2.5 | l.0Max | 22 | 5 | Bal | 0.5Max | 1.8 | 100/270 | 镀锌线轴套、衬套 Galvanizing line bearing shaft sleeves | |

n 自熔性铁基合金粉末Self-fusing iron base alloys Powder

粉末Alloy | 硬度HRC | 化学成分 Chemical Composition | 粒度Mesh Size | 典型工艺 Typical Application | ||||||||

C | Cr | Si | Fe | Mo | Ni | Mn | B | Others | ||||

Fe1 | 35-40 | 0.15 | 22 | 4.5 | Bal | 2 | 13 | 1.6 | 100/270 | 阀门 Valve | ||

Fe2 | 38-44 | 0.15 | 22 | 4.5 | Bal | 2 | 10 | 1.8 | 100/270 | 阀座 Valve seat | ||

Fe5 | 62-67 | 4.5 | 40 | 1.0 | Bal | 0.97 | 1.8 | 100/270 | 钻杆接头 Drilling pipe joint | |||

Fe90 | 50-55 | 0.15 | 13.5 | 1.30 | Bal | 1.6 | 100/270 | 钻杆接头 Drilling pipe joint | ||||

Fe6 | 58-60 | 0.8 | 7.5 | 2 | Bal | 32 | 4 | 100/270 | 风机叶片 Fan blades | |||

Fe45 | 40-46 | 0.6 | 7.5 | 2 | Bal | 22 | 3 | 100/270 | 造纸机Paper-making machines | |||

304 | 0.03 | 18.0 | 0.1 | Bal | 10 | 0.3 | 100/270 | 造纸机Paper-making machines | ||||

316L | 0.03 | 17.0 | 0.2 | Bal | 2.5 | 12 | 0.5 | 100/270 or 300/500 | 造纸机Paper-making machines | |||

410L | 220 | 0.03 | 12.5 | 0.5 | Bal | 0.1 | 100/270 or 300/500 | 活塞Pistons | ||||

JR-1 | 19 | 0.03 | 17.0 | 0.8 | Bal | 0.3 | 1.3 | 活塞Pistons | ||||

JR-2 | 26 | 0.04 | 17.0 | 0.3 | Bal | 0.2 | 2.6 | 活塞Pistons | ||||

JR-3 | 46 | 0.12 | 16.5 | 0.8 | Bal | 0.9 | 活塞Pistons | |||||

JR-4 | 63 | 1.00 | 4.0 | 0.3 | Bal | 5.0 | 0.3 | 活塞Pistons | ||||

Fe253 | 35 | 1.75 | 28.0 | 1.3 | Bal | 4.5 | 16.0 | 0.8 | 100/270 | 发动机气门 Engine Valve | ||

Fe253H | 40 | 2.10 | 28.0 | 1.2 | Bal | 5.5 | 11.5 | 1.0 | 100/270 | 发动机气门 Engine Valve | ||

Fe101 | 62 | 3.3 | 2.0 | 1.0 | Bal | 5.0 | 1.0 | 1.4 | 20/300 | 挤出料桶 Extrusion barrels | ||

Fe102 | 62 | 2.7 | 2.8 | 1.0 | Bal | 5.5 | 1.0 | 1.9 | 20/300 | 挤出料桶 Extrusion barrels | ||

Fe103 | 62 | 1.5 | 4.5 | 1.0 | Bal | 7.0 | 1.0 | 2.9 | W:4.5 | 20/300 | 挤出料桶 Extrusion barrels | |

Fe104 | 60 | 1.7 | 4.5 | 1.5 | 11.0 | 0.8 | 3.0 | 20/300 | 挤出料桶 Extrusion barrels | |||

Fe105 | 62 | 1.5 | 4.5 | 1.3 | 1.5 | 12.0 | 1.0 | 2.8 | 20/300 | 挤出料桶 Extrusion barrels | ||

Fe106 | 62 | 1.08 | 5.42 | 2.01 | 27 | 0.89 | 3.08 | 20/300 | 挤出料桶 Extrusion barrels | |||

Fe107 | 62 | 1.36 | 6.25 | 1.56 | 16.2 | 1.02 | 2.98 | 20/300 | 挤出料桶 Extrusion barrels | |||